The Application of Single Axis, Double Axis, 3DOF, 4DOF, 6DOF motion platform on Simulator

0 Comments

/

Single axis, double axis, 3DOF, 4DOF, 6DOF motion platform can be used for different types of simulators.The dynamic platform naturally interacts with people via mixed senses of sight, sound, thrust and touch, bringing people thrilling excitement and realistic simulation experience.

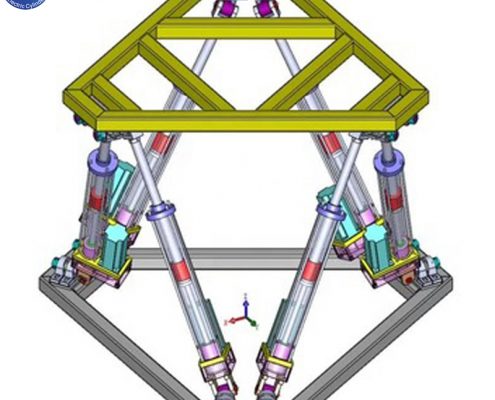

How to build a 6 DOF steward motion platform simulator

The simulator system is composed of multi-degree of freedom motion platform, computer control system, motor drive system, etc.. The bottom platform is fixed on the ground and the top platform is for supporting the load.

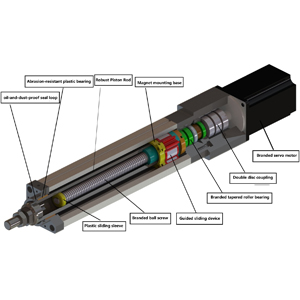

Discover The Inside of Electric Cylinders

The Structure of Electric Cylinder:

The electric Cylinders…

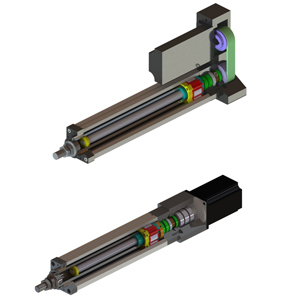

The Difference between Inline Electric Cylinder and Parallel Electric Cylinder

The cost of both types are the same, inline electric cylinder connects the ball screw drive and motor shaft by coupling, the parallel type electric cylinder connects the ball screw drive and motor shaft by pulley.

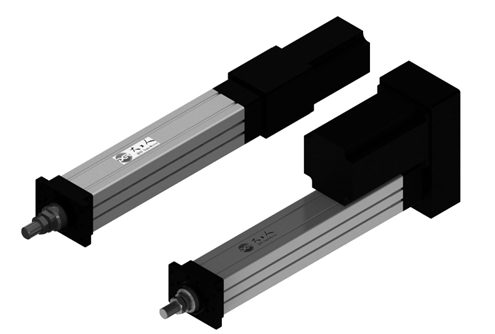

Features of DGR Electric Linear Actuators

DGR electric linear actuators are produced at the highest standards with carefully seleted materials to meet customers' requirements for the life span and positioning precision, all the parts are machined by CNC machines, with compatibility with motors from all manufacturers in the world.

DGR Electric Cylinder linear actuators apply for solar tracking system

Electric cylinder linear actuators are used to orient the solar panels toward the sun for higher efficiency, solar tracking systems are also often used in large commercial projects, rooftops, or home PV tracking equipment.

How Does The DMX512 Control Console Control The Movement Of The Electric Linear Actuators

How does the DMX512 control console control the movement…

Why Use Electric Linear Actuators?

Electric linear actuators are more cost-effective than their hydraulic and pneumatic counterparts. Electric actuators benefit from cleaner, simpler, and more energy-efficient power transmission. Electric actuator integration is easier with programmable controls, and maintenance is minimized with no parts replacement or lubrication needed except in extreme conditions.